The largest single nozzle rocket engine in history

In the 1950s, the newly formed NASA needed a very large rocket engine – enter the Rocketdyne F-1. The F-1 became a show of power both literally and figuratively during the cold war. NASA used it in its early space missions, including Apollo XI, humankind’s first trip to the moon.

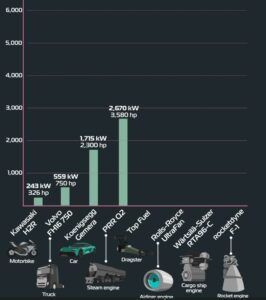

The F-1 is the largest single nozzle rocket engine in history. It produced 6.8MN (1,522,000 lbf) of thrust at sea level. This is almost four times that of the RS-25, the Space Shuttle’s main engines.

For a more worldly comparison, the engines on a Boeing 747 each produce around 0.25MN of thrust. That means the F-1 is 27 times more powerful than a large airliner engine. And the Saturn V rocket, which had five R-1 engines, was driven to a speed of 9,920 km/h (6,164 mph) in two and a half minutes!

Only the Russian made RD-170 engine produces more thrust than the F-1. The RD-170, however, uses a multi-nozzle and combustion chamber design.

The basics of rocket engine function

Rocket engines use a controlled explosion to provide thrust. A more formal term for this type of explosion is combustion.

Combustion is what you get when fuel and oxygen react with each other. The result is a violent expansion of gases and heat. Directing these gases in a certain direction creates thrust in the opposite direction – as per Newton’s third law.

Unlike jet engines, which take in oxygen from the air, rocket engines use oxygen carried onboard along with the fuel. This allows rocket engines to be much more powerful, albeit with some extra challenges. For one, oxygen needs to be kept in the liquid state for a rocket to carry enough of it. In order to store it as liquid oxygen (LOX), it must be cryogenically cooled to very low temperatures, as it has a boiling point of -183 degrees C (-297 degrees F).

How the F-1 engine works: the gas generator cycle

There are a few variations in rocket engine design. The F-1 rocket engine used the gas generator cycle.

With the gas generator cycle, some fuel and LOX is diverted away from the combustion chamber and towards the gas generator. Here, a smaller amount of combustion occurs to drive a turbine. This turbine then powers two turbopumps – the fuel turbopump, and the LOX turbopump. These turbopumps feed the main combustion chamber with fuel and LOX.

The gas generator is an open rocket engine design. This is because the engine expels the exhaust gases from the gas generator without it contributing to the main combustion. A closed system, on the other hand, does not have a separate exhaust system for turbine combustion.

How the F-1 produces so much thrust

The F-1 engine’s turbine has a power output of 41MW. This is 41 times more powerful than the engine of the fastest production car in the world, the Koenigsegg Agera. And this power is just pumping the fuel – it’s not even the main event.

With the amazing turbopump power, the F-1 consumes 788 kg/s (1,738 lb/s) of RP-1 fuel and 1,789kg/s (3,945 lb/s) of LOX! Because combustion power grows with propellant flow rate, the F-1 achieves its mighty levels of thrust through its ravenous consumption of fuel.

With this thrust also comes heat. To keep the nozzle from melting, the RP-1 fuel has a secondary mission. It absorbs heat from the nozzle as it passes through a void prior to reaching the combustion chamber. In doing so, the fuel is heated, and the nozzle is cooled which prevents it from reaching critical temperatures.

The F-1's legacy and current rocket engine designs

The R-1 belongs in the engineering hall of fame. Its design overcame incredible challenges to achieve things the world had never seen before. And in some ways, will probably never see again.

Modern rocket engine designs are smaller and less powerful. This is to find a balance with other requirements aside from thrust. Many new designs, like the SpaceX Raptor engine, consider reusability and cost per flight to make space launches more economical. This was not part of the equation when NASA was given a blank check for the Apollo program.

Another reason we won’t see anything like the F-1 again is the craftsmanship it needed to make. Back in the 1950s, hands-on skill ensured the final product was up to the task. Today, advanced manufacturing has replaced manual labour, and in the process we have lost the intricate know-how of the F-1’s construction. Something of a similar spec built today, will look pretty different.

It’s not unreasonable to expect humanity’s future lies among the stars. To what extent, it’s hard to know. But without doubt, the Rocketdyne F-1 paved the first steps in that direction.