A brief history of the internal combustion engine

Imagine life without the internal combustion engine (ICE). We would struggle to get around, supply chains would freeze, and our lawns would look pretty shabby. For these reasons, few 19th century inventions have had a greater impact.

Almost since its invention, the ICE has had two distinct mechanical cycles of which it can operate – the two-stroke cycle and the four-stroke cycle. Both continue to be used today, and each come with their own pros and cons.

The modern two-stroke engine is best attributed to English engineer Joseph Day. He came up with his novel design in around 1889, and it was first used in electric generators. Despite the long-term success of his invention, Day’s career and life sadly slipped into obscurity. A series of lawsuits and bankruptcy pushed Day away from public view for decades until his death in 1946. So much so, a museum’s search for biographical info on Day came up empty-handed. And this was only five years after his passing.

The four-stroke engine was invented three decades earlier in 1861 by groceries salesman-turned-engineer, Nicolaus Otto. The first versions of the engine were not a major success – they only ran for a few minutes before they self-destructed. Undeterred, Otto founded the first ICE company in 1864. From there, Otto and the wider industry developed the four-stroke ICE to the point where they were being used in early automobiles some 20 years later.

How the two-stroke cycle operates

The strokes of the two-stroke engine are:

1. The power stroke

Fuel and air combust inside the engine cylinder, which produces a rapid increase in pressure. This forces the piston downward from Top Dead Centre to create rotational movement at the crankshaft.

The combusted gases exit the cylinder through the exhaust port. The exhaust port is only open when the piston has dropped past the exhaust port level.

Fresh fuel and air enter the cylinder during the same cycle. The piston’s downward motion forces fuel and air from the crankcase and up through the transfer port. Like the exhaust port, the transfer port is only open when the piston has dropped below its level.

During the power stroke, positive pressure in the crankcase forces the reed valve to close. This stops fresh air and fuel from entering the crankcase.

2. The compression stroke

Once the piston reaches Bottom Dead Centre, it moves in an upward motion. This creates negative pressure in the crankcase which opens the reed valve. Fresh fuel and air then flows into the crankcase.

The fuel and air inside the engine cylinder becomes trapped as the piston closes the transfer and exhaust ports. As the piston reaches Top Dead Centre, the active volume of the cylinder lowers, and the pressure of the air and fuel increases.

How the four-stroke cycle works

As its name suggests, the four-stroke engine has two additional strokes. Each of the four strokes are:

1. The intake stroke

The piston moves down from Top Dead Centre and creates negative pressure inside the engine cylinder. An intake valve, perfectly timed by a camshaft, opens at this moment. This sucks fresh fuel and air into the cylinder.

2. The compression stroke

Once the piston reaches Bottom Dead Centre, it reverses its direction to move upwards. During which, the intake valve closes and the air and fuel are compressed as the piston lowers the active volume of the cylinder.

3. The power stroke

The fuel and air combust as the piston reaches Top Dead Centre. This causes a rapid increase in pressure and forces the piston downwards to produce rotational movement at the crankshaft.

4. The exhaust stroke

As the piston again passes Bottom Dead Centre and moves in an upward motion, a precisely timed exhaust valve opens. The piston forces the combusted gases out through the exhaust.

Two-stroke vs. four-stroke - which is more powerful

In short, the two-stroke engine is more powerful. This is because the power stroke occurs twice as often compared to the four-stroke engine. But do not be fooled, this does not mean it is twice as powerful.

To help explain why, refer to the Pressure vs Volume charts on the schematic. These plot the cylinder volume by pressure and are useful for looking into engine performance. The swept area of the chart is equal to the mechanical work done (or energy output) during each full cycle. And the work done by the engine divided time, gives the power output.

As you can see from the Pressure vs Volume charts, the shaded area of the four-stroke cycle is greater, which means it provides more power. This is because of the finer exhaust and fuel intake – referred to as engine scavenging. The superior engine scavenging of the four-stroke engine allows for:

-

Higher compression of the fuel and gas prior to combustion. This makes the combustion more powerful.

-

Proper exhaust of the combusted gases. This avoids polluting the fuel in the following cycle.

-

A fuller power stroke with the pressure of the combustion forcing the piston down all the way to Bottom Dead Centre. With the two-stroke engine, some of the combustion pressure is lost through the exhaust.

So, for engines of the same size and running at the same RPM, the two stroke is more powerful. However, they are not twice as powerful because of the stronger power stroke of the four-stoke engine.

What about RPM and torque?

The subject of engine power gets more complex when RPM (Revolutions Per Minute) is considered. The metric formula for engine power with respect to RPM is:

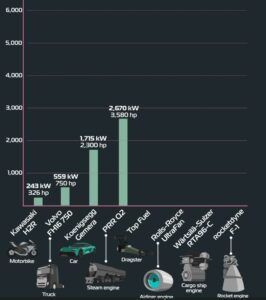

Power = Torque x π x RPM / 30

What is torque? Torque is turning force. Something with high torque can continue to spin against high resistance. Think of a truck hauling a huge load – high torque is applied to the wheels so it can keep on truckin’ on.

So, according to this formula, if an engine is operating with a high amount of torque and high RPM, then the power output will also be very high!

Two-stroke engines have a distinctive power band where they produce higher torque (and therefore power) at higher RPMs. This gives two-stroke motorcycles their distinctive power ‘kick’ while already travelling at speed. The power band occurs at higher engine RPMs where two-stroke engine scavenging is more effective.

Four-stroke engines, on the other hand, tend to have comparatively higher torque at lower RPMs. This makes them better for towing and possibly faster off the mark when used in vehicles.

The max RPM of an engine also affects the max power output. An engine will generate more power at a higher RPM until it reaches redline, where the scavenging starts to fail. However, there are many factors aside from being two-stroke or four-stroke that determine an engine’s max RPM. Therefore, it is hard to pick a winner here.

Two-stroke vs. four stroke - which is more efficient?

The four-stroke engine is more efficient. But this is not because the engine only fires half as often as some sources suggest. The additional strokes of the four-stroke cycle do not provide mechanical work and therefore are not a factor in the engine’s efficiency.

The greater combustion pressure of the four-stroke engine is the reason for greater efficiency. If two engines use the same amount of fuel for the power stroke, but one is more powerful, then it must also be more efficient!

Further reducing efficiency, the imperfect scavenging of the two-stroke engine allows some unburnt fuel to be exhausted before it gets a chance to combust. This occurs because the transfer and exhaust ports are briefly open at the same time.

Other pros and cons of each engine cycle

Aside from efficiency, other advantages of the four-stroke engine include:

Cleaner emissions. Two-stroke engines require oil to be mixed with the fuel, which creates dirty emissions. Four-stroke engines do not burn oil when running properly.

Less noise. The exhaust valves of the four-stroke engine muffle the combustion noise. Whereas, the open exhaust port of the two-stroke cycle allows a lot of noise to radiate from the engine.

Because of these reasons, modern vehicles are exclusively four-stroke. Emissions regulations in particular have pushed two-stroke engines out of the vehicle arena.

Aside from power, other advantages of the two-stroke engine are:

Lighter construction, which gives them higher power-to-weight ratios.

Less complexity with no engine valves, camshafts and other mechanisms needed. This allows them to be cheaper to make.

Because of these reasons, two-stroke engines are often used in small handheld devises like chainsaws and whipper snippers.